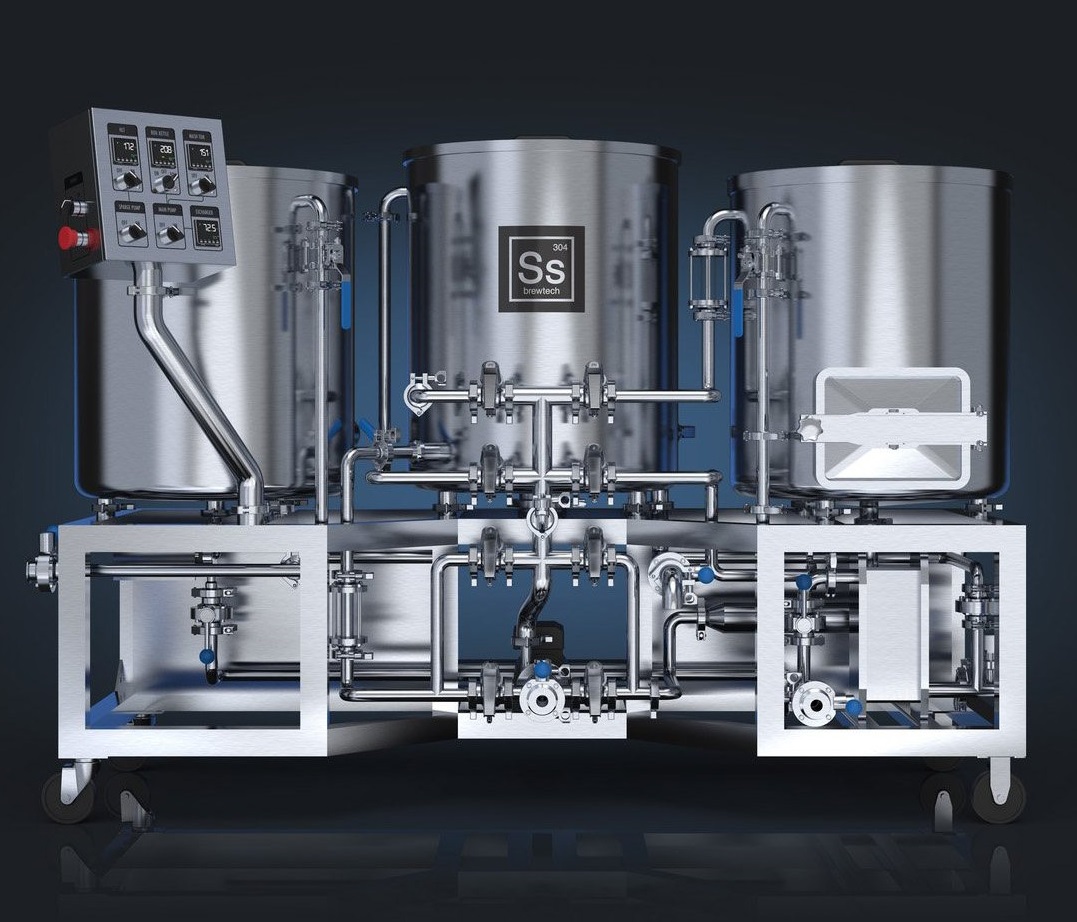

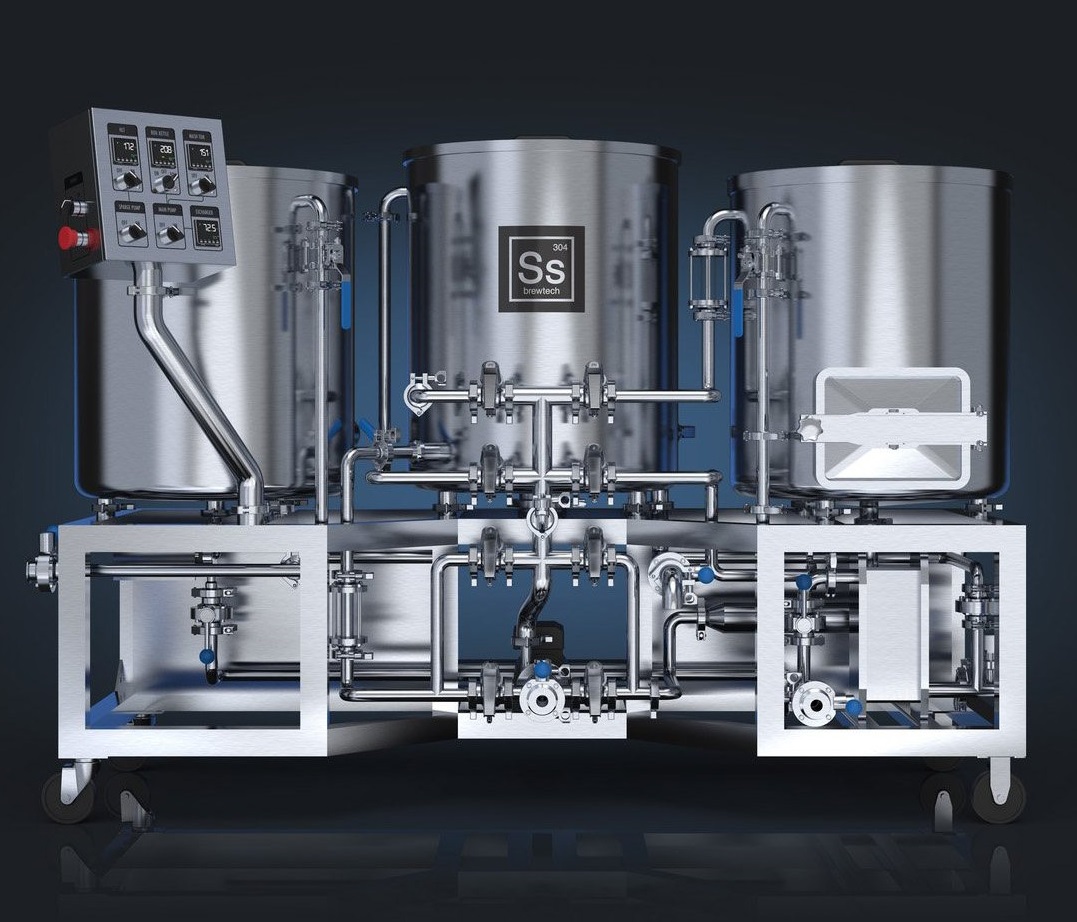

Ss Brewhouse 1 BBL

Hembryggeri

Prisjämförelse

Produktinformation

Lägsta pris på denna produkt är 0 kr.

When we began designing the 1 bbl Brewhouse we knew we didn't want to simply scale up our home equipment line. Instead, we took everything we've learned designing, operating, and executing full size professional brewhouses around the country and scaled it down. The result of this approach is a professional grade nano brewhouse with no equal. Engineering better beer. That's what we do.Heating & Internal CalandriaWe have designed the heat sources and electrical framework of the 1 BBL brewhouse to enable the brewer precise control over each temperature and process. At the core of that objective are independent heating elements for each vessel, allowing the user to dial in the perfect strike and sparge temp in the HLT, sustain or step mash temps through the integrated RIMS tube, or modulate the perfect rolling boil via the proportional heat control in the kettle. Patent Pending Valve TreeDrawing from the brewer-centric design of our pro brewhouses lead us to the key design feature of this system, the valve tree. Placing all the critical process valves in one central location makes the brew day intuitive and enjoyable. The control panel is a scaled down version from our larger pro brewhouses. The entire brewhouse is built upon a network of sanitary welded and fully hard piped TC connections. The integral hard piping matched with a fully welded frame provides a fit and finish never before seen in a 1 bbl brewhouse.Milled False Bottom & Grain-OutYou won't find a punched false bottom on any of the professional brewhouses we design, and we felt there was no place for one on the nano brewhouse. The precision milled false bottom allows for a faster vorlauf, clearer run off, and mitigates the risk of a stuck sparge. The pro inspired grain-out door allows for quick and easy clean up. Tip and dump, or scooping grain from the top of a mash tun are a thing of the past.Features:3 heating elements (Boil Kettle, HLT, and RIMS)Internal Calandria around Boil heating elementsTangential whirlpool portStainless hard pipping throughout with valve treePerlick Style sampling valveDetachable CIP armSparge ringCombo Vorlauf/Strike water fill portDedicated underlet legProportional heating element control with Omron PID Controllers combined with dynamic voltage adjustabilityMain control panel with HLT, Mash, Kettle, and heat exchanger temp readoutsDedicated pump control switchesDual cart mounted electrical service panelsSpecs:1 bbl final batch size20% kettle headspace2.5mm kettle wall thickness2B Mill Finish1” process piping1” ID butterfly valves, sight glasses, and TC gaskets1 Square Meter Heat Exchanger surface area74" width x 52" height x 40" depthPower requirements:Limited Mode, Kettle OR HLT + RIM = 32amp CircuitUnlimited Mode, All heating elements = 50amp CircuitHLT = 7.5Kw @ 400VAC Kettle = 10.5Kw @ 400VAC RIM = 3.0Kw @ 400VAC 1BBL Brewhouse FAQ

Kategorier

Avsett för vuxna

Avsett för vuxna

Bebis och småbarn

Bebis och småbarn

Djur och tillbehör till husdjur

Djur och tillbehör till husdjur

Elektronik

Elektronik

Fordon och delar

Fordon och delar

Företag och industri

Företag och industri

Hem och trädgård

Hem och trädgård

Kameror och optik

Kameror och optik

Kläder och accessoarer

Kläder och accessoarer

Konst och underhållning

Konst och underhållning

Kontorsmaterial

Kontorsmaterial

Leksaker och spel

Leksaker och spel

Mat, dryck och tobak

Mat, dryck och tobak

Media

Media

Metallprodukter

Metallprodukter

Möbler

Möbler

Programvara

Programvara

Religion och ceremonier

Religion och ceremonier

Resväskor och väskor

Resväskor och väskor

Skönhet och hälsa

Skönhet och hälsa

Sportartiklar

Sportartiklar